J-STD-001 Training Kit – Purpose, Scope, Elements

The IPC (Association Connecting Electronics Industries) developed the J-STD-001 standard to provide performance parameters and quality control processes for soldered electrical and electronic components. It outlines best practices for producing, inspecting, and testing these assemblies to ensure they meet specifications and can be relied upon. You can get a J-STD-001 training kit and use the J-STD-001 standard as a reference for soldering operations and quality control.

Purpose and Scope

Regarding electronics, the J-STD-001 standard outlines the rules for how they should be soldered together. The IPC and Joint Electron Device Engineering Council (JEDEC) collaborated to create the industry-standard soldering rules termed J-STD-001.

The goal is to define standards for making solder joints that are impenetrable and fail-safe. The bar covers both through-hole and surface-mount soldering methods. Aerospace, automobiles, medicine, telecoms, and consumer electronics are just a few of the many fields it touches.

Key Elements of J-STD-001

The J-STD-001 standard makes it easier to create high-quality soldered systems because it covers many important factors. Included in the scope of the standard are the following elements:

- Soldering Materials: The standard specifies what should be included in solder alloys, fluxes, and other supplies. It lays down the requirements for a muscular soldier junction, including the materials and their compatibility.

- Soldering Processes: Soldering methods such as hand soldering, wave soldering, and reflow soldering all have rules in J-STD-001. It describes how to establish solid solder junctions and what temperatures, dwell durations, and other factors to consider.

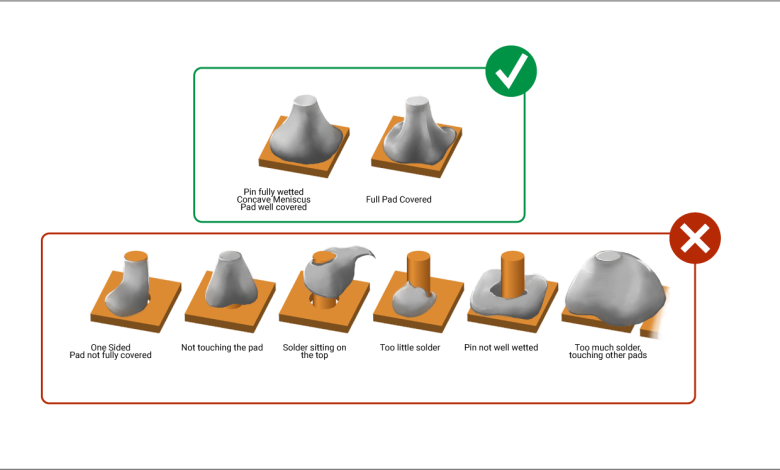

- Solder Joint Acceptance Criteria: Acceptance requirements for solder junctions are spelled out in the standard, and they are based on factors, including how the joint looks and how well it holds together. It gives criteria for evaluating fillet formation, wetting, and solder flow.

- Component Preparation: Lead forming, trimming, and tinning are all part of the soldering prep work that J-STD-001 addresses. It ensures the claims are clean and ready for a good solder joint.

- Inspection and Testing: Solder joint inspection and testing procedures are outlined in the standard. It includes visual inspection techniques, automated inspection methods, and electrical testing to identify and assess solder junction quality and reliability.

- Repair and Rework: Instructions for fixing and reworking soldered assemblies are provided in J-STD-001. It describes how to disassemble, reassemble, and repair solder joints and ensure that a selected group will work reliably.

Training and Certification

The J-STD-001 training and certification program aims to produce personnel fully conversant with all legal aspects and can apply them competently in practice. J-STD-001 courses are available from IPC-approved training facilities, and they address the requirements of the middle and provide opportunities for practical application.

It is typical for the classroom portion of the training program to include soldering processes, artistic standards, and approval criteria as outlined in J-STD-001. There are also exercises that you may apply in the actual world to strengthen your understanding and application of the standard. Test-outs may be available to participants, including soldering and inspecting sample assemblies.

After completing the coursework, participants can take a certification test based on J-STD-001 to determine how well they have retained the material. One must pass the certification to prove competence in producing soldered assemblies that adhere to the standard.

Importance in the Electronics Industry

There are several reasons why J-STD-001 is so essential to the electronics sector:

- Quality Assurance: The standard guarantees the durability and high quality of solder electrical and electronic assemblies. Adhering to J-STD-001 can help you minimize solder joint failures such as opens, shorts, and cold solder junctions, which may result in functional issues or product failures.

- Consistency and Interoperability: J-STD-001 encourages uniformity and interoperability between manufacturers and suppliers by outlining explicit norms and approval criteria. Because of this, electronic gadgets may have their parts integrated and assembled more quickly and easily.

- Customer Confidence: Customers may be sure that the soldered assemblies they get are up to par because of the standardization required by J-STD-001. Customers may rest easy knowing the things they buy are trustworthy and high-quality.

- Industry Compliance: Soldered assemblies are required to meet standards in various sectors. J-STD-001 guarantees conformity to standards and regulations unique to specific industries, such as the aerospace, automotive, and medical sectors.

- Professional Development: Gaining J-STD-001 certification might set you apart from the competition in the employment market. Professionals who get a soldering certificate demonstrate their expertise and commitment to creating high-quality soldered assemblies, which opens doors for them in the cutthroat electronics industry.

Revision and Updates

The J-STD-001 standard undergoes frequent updates to adapt to changing consumer preferences, new technological developments, and expert recommendations. To meet the fast expansion of the technology industry, adjustments must be made often.

Maintaining the J-STD-001 standard requires collaboration between experts, manufacturers, and anyone interested. To make the standard more useful and widely applicable, they take into account comments, add new research results, and keep an eye on developing technology.

Conclusion

The J-STD-001 standard offers exhaustive standards for soldered electrical and electronic components. Solder junctions retain their integrity, quality, and cleanliness. People and businesses in the electronics industry can benefit significantly from the J-STD-001 training and certification program, which gives them the skills to make soldered systems free of flaws and meet industry standards.